For years, Leku-Ona has specialised in products and fittings for low, medium, high and very high pressure hydraulic oil systems. This is why flexible stainless steel hoses have become the best ally for tackling projects with very special characteristics in extreme conditions, which is what usually happens in sectors such as the machine tool, maritime, steelworks and farming industries, to name a few.

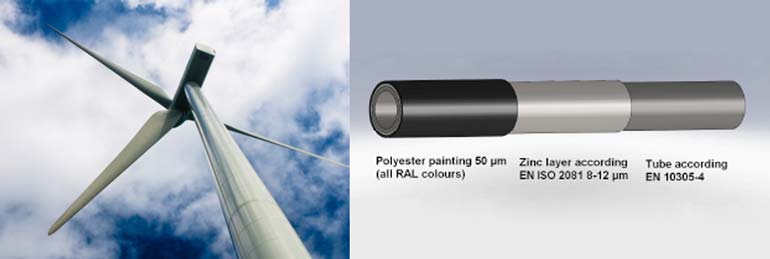

At our site in Itziar (Deba), we offer corrugated hoses without mesh, or with one or two layers of mesh. They can withstand temperatures of -270 ºC to 600 ºC and compensate for the thermal expansion or contraction in the hose system.

At our site in Itziar (Deba), we offer corrugated hoses without mesh, or with one or two layers of mesh. They can withstand temperatures of -270 ºC to 600 ºC and compensate for the thermal expansion or contraction in the hose system.

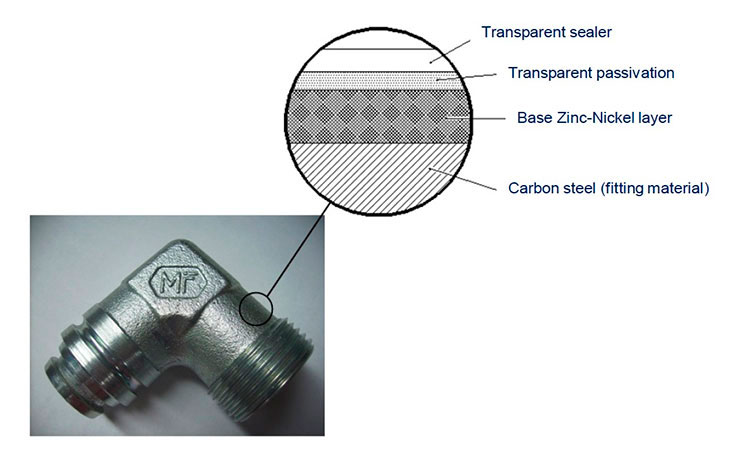

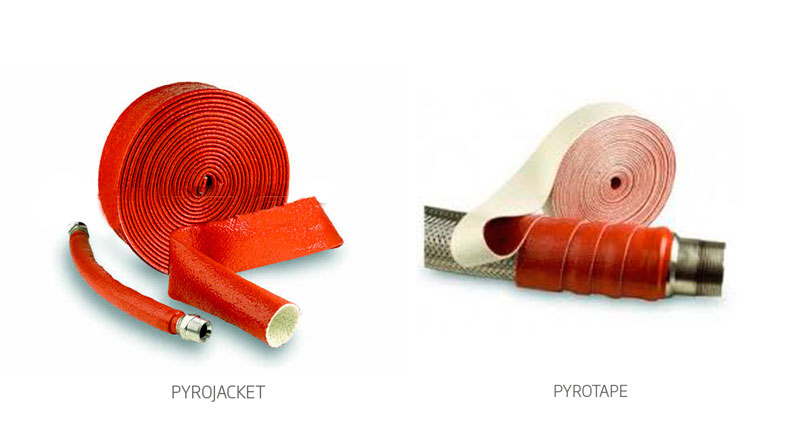

These kinds of hoses are also resistant to fire, humidity, abrasion, penetration and damage which may arise in the environment where they are being used due to their excellent anti-corrosion properties and their high physical strength.

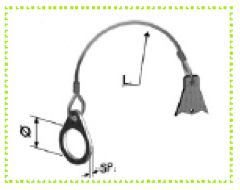

Nevertheless, this resistance does not prevent them from being tailored to places and areas which are difficult to access, which is why they have come to play an important role in all kinds of industrial applications.

At Leku-Ona Global Solutions, we custom manufacture flexible stainless steel hoses for our clients, personalising the product as much as possible so that it meets the specific needs of each client and satisfies the characteristics of each project.

More information:

If you would like to receive advice on how to fit flexible hoses or information about them please get in touch with us by calling | Tel.: 34 943 74 34 50 or by writing to | Email: leku-ona@leku-ona.com

sending...

sending...