Nexo Fittings (representing the Leku-Ona group) will be present at the next edition of EXPONOR CHILE 2019 with its own exhibition stand located in the pavilion COBRE, stand nº157. This stand is located within the Spanish pavilion of EXPONOR2019. EXPONOR is an event held every two years in the mining region of Antofagasta, one of the important mining areas of the Americas. . Exhibiting thus becomes one of the meeting points for the exchange of business, knowledge and experiences of this industry. The fair is organized by the Industrial Association of Antofagasta and sponsored by the Mining Council of Chile, the Regional Government of Antofagasta, Prochile, SONAMI and SOFOFA.

Nexo Fittings started its journey in Chile in 2018. Thanks to the commercial work developed during these last months, it has become known among the professionals of the hydraulics sector. In order to strengthen our presence in the Chilean market and bring our products to the main mining basins and companies linked to the mining sector, Nexo Fittings participates for the first time in one of the main fairs worldwide in this sector: EXPONOR 2019.

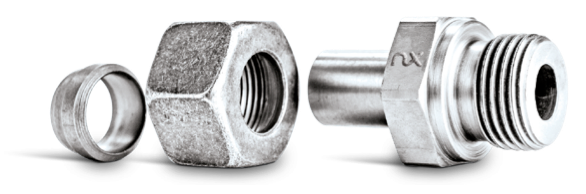

Its main objective is to present the range of steel connections, according to ISO 8434-1 / DIN 2353, and designed safely and without leaks for the connection of metric pipes with diameters from 4 to 42 mm in the light series , very light and heavy. Likewise, he will take advantage of the occasion to promote the hydraulic hose of high pressure with brand LOHT (Leku-Ona Hydraulic Technology), manufactured in Spain according to the standards SAE (United States), BS (United Kingdom), and EN (European Union), used in multiple applications: oil, paint, hot water, etc., and for various industrial sectors: mining, agriculture, wind, machinery, etc.

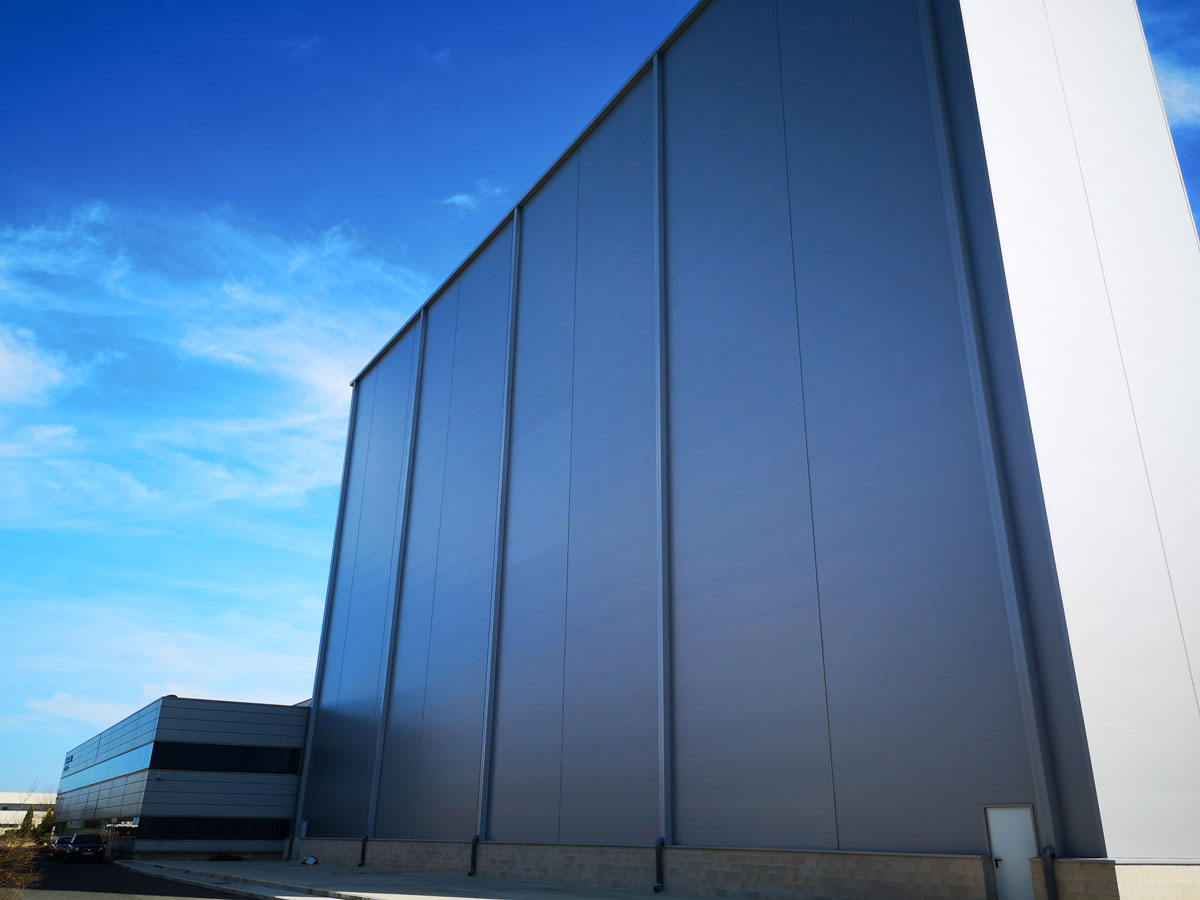

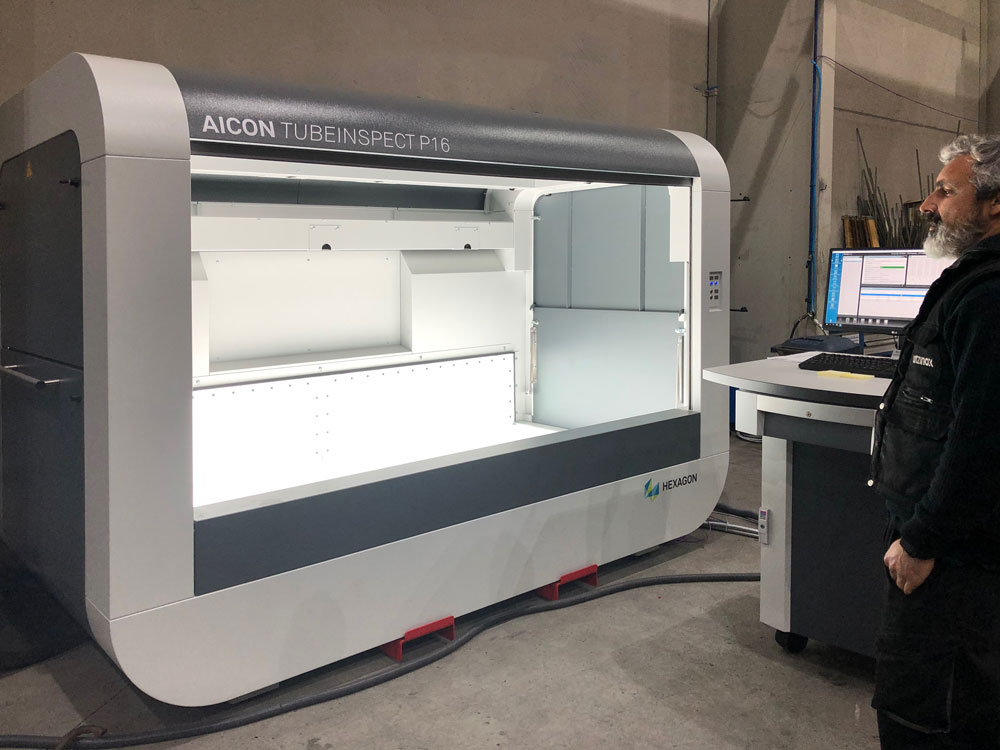

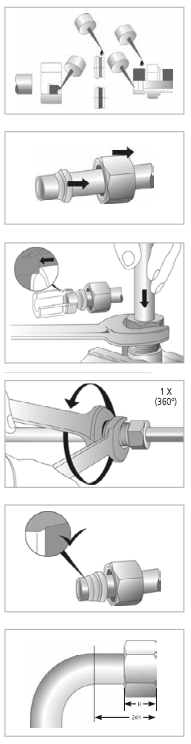

2.- Tube preparation

2.- Tube preparation

sending...

sending...