LOAM (Leku-Ona Additive Manufacturing) was created in 2017 in Itziar-Deba, Gipuzkoa (Basque Country – Spain), with the backing of the group Leku-Ona Global Solutions and with the aim of offering additive design and manufacturing services.

Using the latest FDM® printing technology, the company guarantees its customers parts of high quality, both for prototyping and for final use, adapted to different sectors and achieving lighter, more efficient and faster production components than those obtained in conventional production.

FDM technology is a manufacturing process used for the modelling of prototypes and small-scale production. Fused deposition modelling uses an additive technique, depositing the material in layers to form the part. A plastic or metal filament that is initially stored in rolls is introduced into a nozzle. The nozzle is at a temperature above the melting point of the material and can be moved over three axes, being controlled electronically.

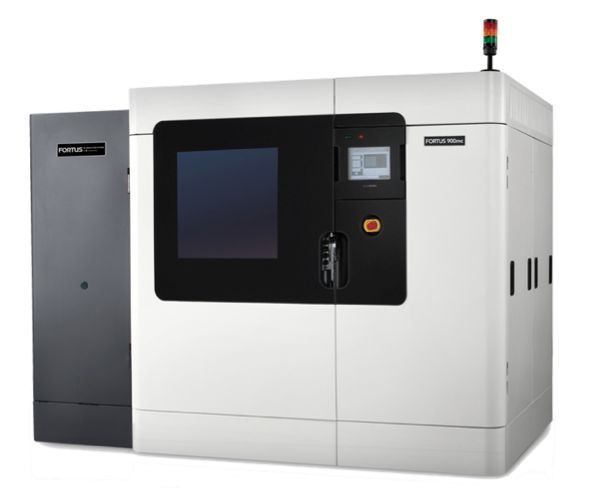

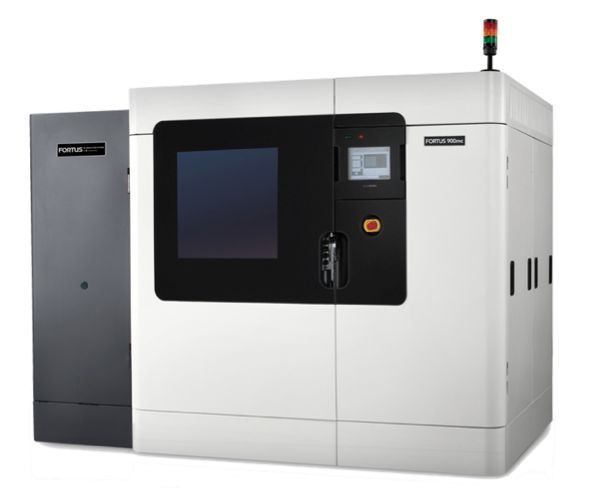

For this purpose, LOAM has the largest and most powerful industrial 3D printer on the market, the Stratasys Fortus 900mc, which incorporates the latest innovative technologies in order to produce precise and functional parts. It has a printing tray with a size of up to 914x609x914, allowing for the manufacture of large, customised parts with a wide range of possibilities.

In addition, the different materials used for manufacture —such as the resins ULTEM®1010 and ULTEM®9085, Nylon 6 and ASA thermoplastic— extend the possibilities of manufacturing different types of parts –such as hardware, customised tools, prototypes, etc.– for a wide variety of sectors, ranging from the automotive and aerospace sectors to the food and medical sectors.

The Leku-Ona family continues to grow

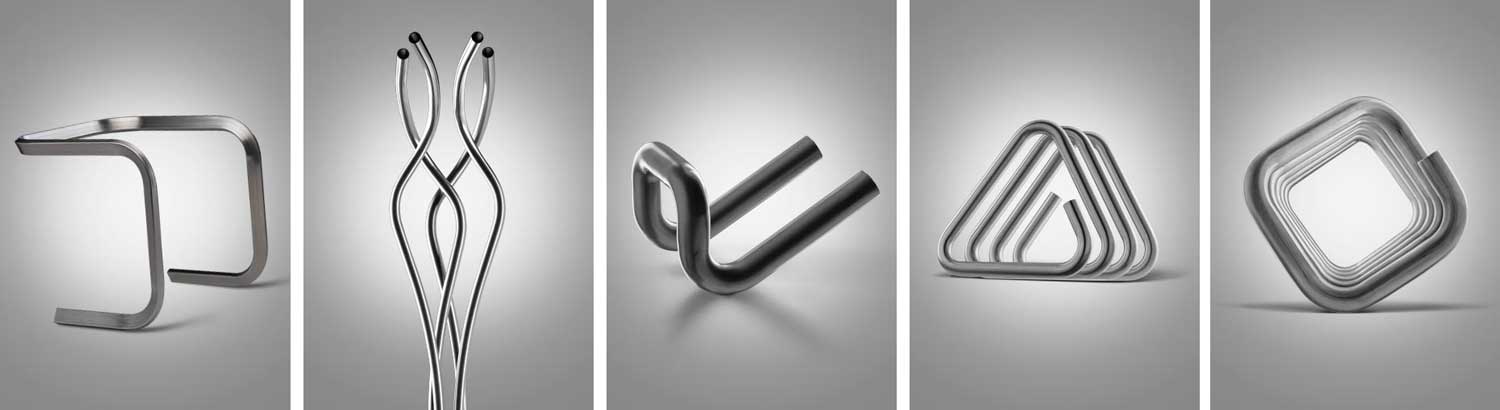

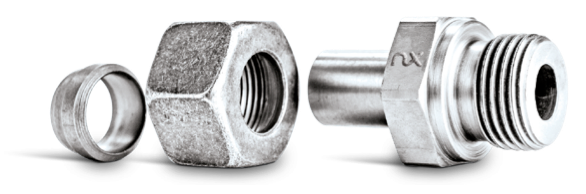

Leku-Ona is capable of offering solutions that respond to the needs of the market thanks to the strength of a group made up of Leku-Ona Commercial (manufacture and marketing of a wide range of products and components related to automation in the areas of hydraulics and pneumatics, as well as tube forming), Urtzinox (design and optimisation of processes related to supply, logistics and manufacturing), MKL (machining and laser cutting), BOSTAK (assembly and hydraulic and pneumatic system solutions), Nexo Fittings (design, manufacture and global marketing of hydraulic fittings for pipes and flexible tubes) and now Leku-Ona Additive Manufacturing (design and additive manufacturing).

These all have a strategic approach that is based on an attitude of constant searching and improvement in their corresponding fields of activity and the synergies that are created between them. The synergies offer many benefits and oblige us to maintain a state of continuous improvement, a feature of the group which makes Leku-Ona Global Solutions especially proud.

About LOAM

Mission

Mission

LOAM, through additive manufacturing and FDM technology, designs, manufactures and markets lighter, more efficient and faster production components than those obtained with conventional production, adapted for any sector.

Vision

The vision of the company is to position itself as a company at the forefront of its sector in innovation and digital technology, and one that offers cutting-edge services.

Values

Values

Reliability and safety

- Innovation

- Leadership

- Commitment

- Ethics and social responsibility

Contact

For more information, please contact:

Sergio Hurtado

loam@leku-ona.com

Pol. Industrial Itziar Nave N2B

20829 ITZIAR-DEBA (GIPUZKOA)

T 943 74 34 50

Mission

Mission Values

Values

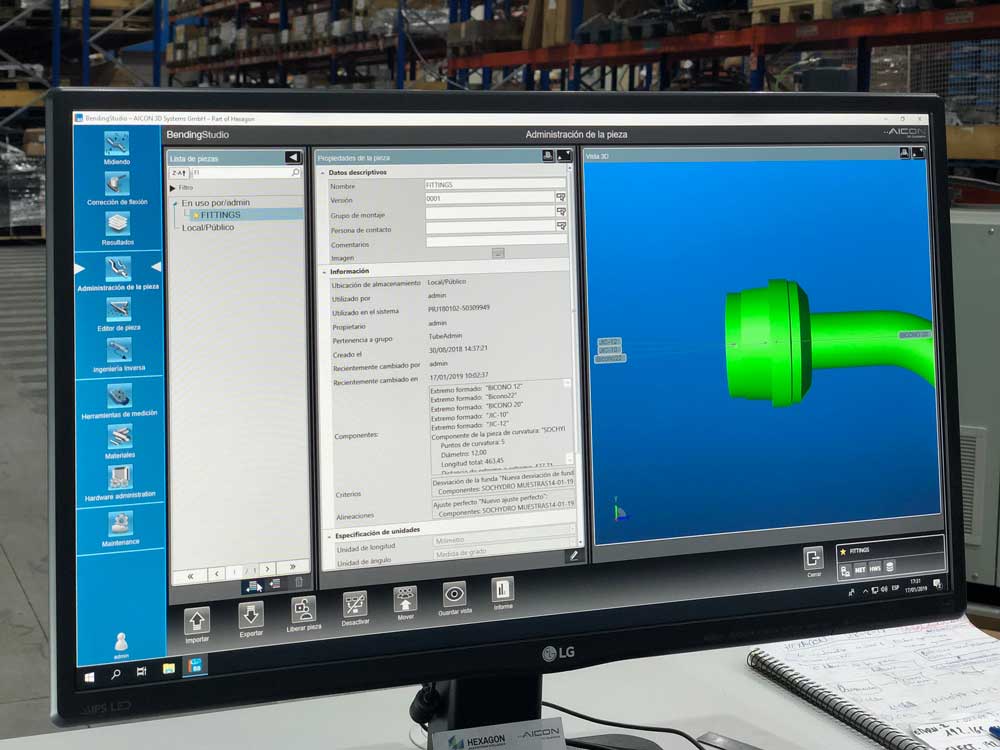

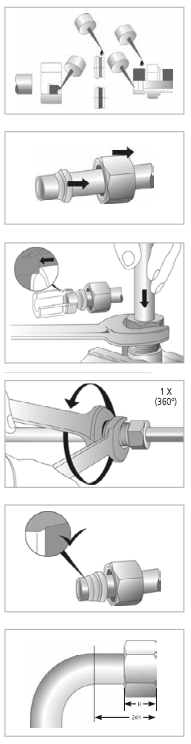

2.- Tube preparation

2.- Tube preparation

sending...

sending...