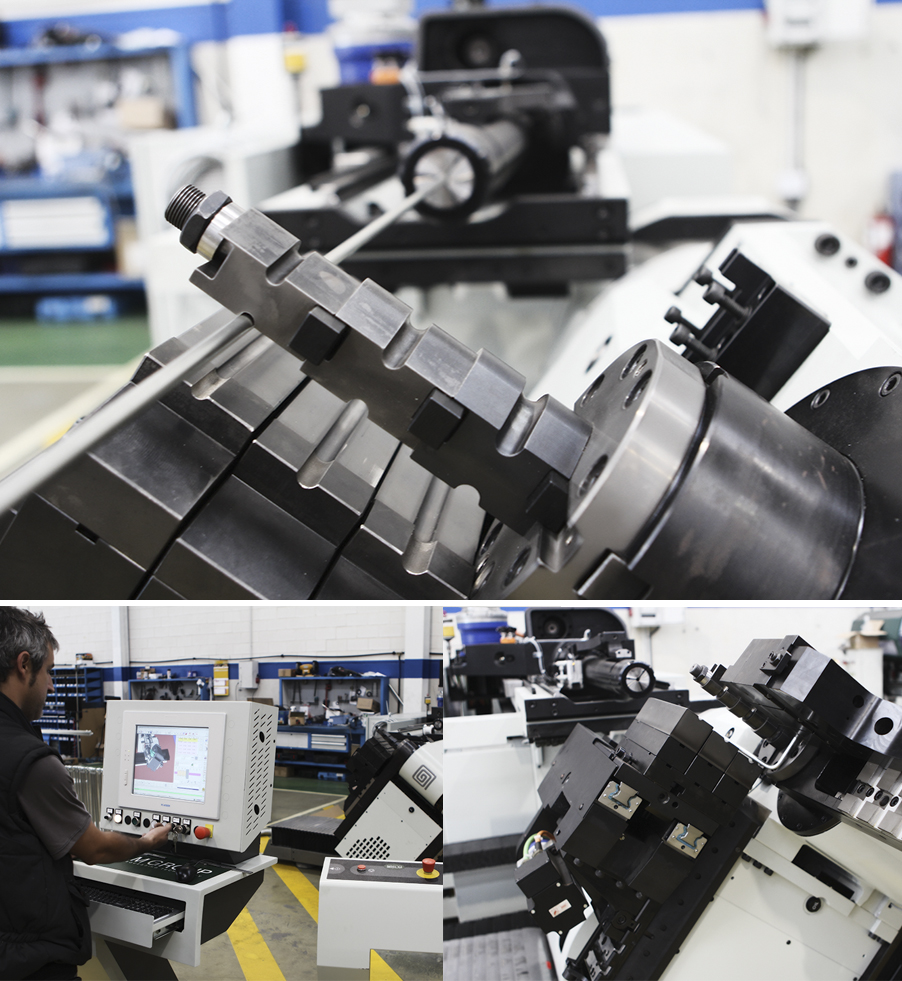

Many customers struggle in mounting the spirals, especially on large hose bundles

With the Safe Bundler tool you can easily mount Safe-spirals starting from OD 75mm up to hose bundles with a maximum diameter of 180-200mm. The tool opens the spiral to be moved forward by an electric drill.

Mounting process becomes much easier and it saves so much time so it pays itself back quickly. The tool can be used also for single hoses.

It is highly recommended to bundle the hoses together with straps first to help keep the hoses together during the mounting process and to guarantee a safer and smoother mounting.

In addition to being very fast and easy, the mounting is ergonomic and reduces the physical strain of operators’ wrists.

For additional information do not hesitate to contact this email leku-ona@leku-ona.com or through

LEKU-ONA_Global Solutions

Pol. Industrial Itziar Nave N2B

20829 ITZIAR-DEBA (GIPUZKOA)

T 943 74 34 50

F 943 74 34 62

E leku-ona@leku-ona.com

www.leku-ona.com

sending...

sending...