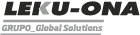

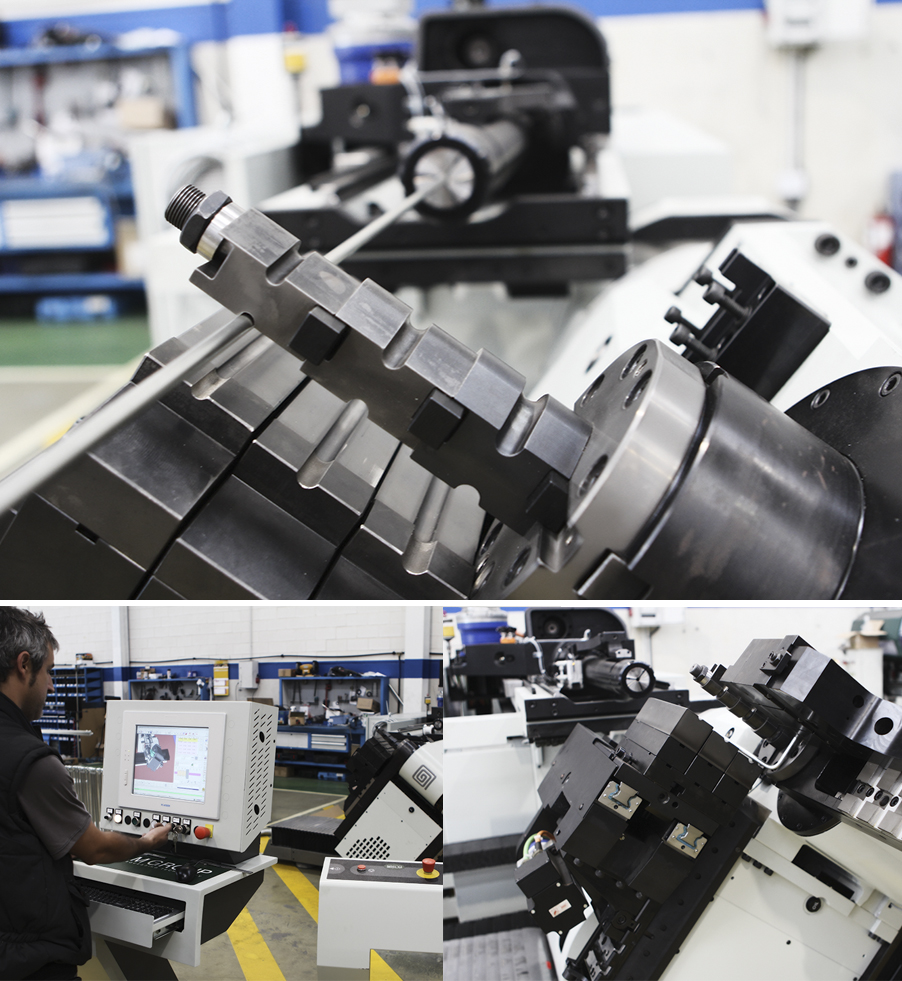

Leku-Ona has recently purchased a new BLM tube bending machine that will complete the requirements of the bending section.

This means that the tubes section of Leku-Ona Global Solutions now comprises 6 bending machines with diameters ranging from OD: 4mm to OD: 102mm for bending carbon steel, stainless steel, copper and brass tubes.

The main features of the new BLM ELECT (ET 102) tube bending machine are:

– The three-dimensional VGP3D graphic programming software: verifies the real possibility of producing the parts, eliminating the risk of collision typical of the first test. It calculates the actual cycle time in advance, reducing the time needed to prepare quotes, and automatically generates the machine cycles.

– Multi-radius: the machine works in multi-radius mode or with different blocks for curves and reverse curves.

– Right or left: you can choose the direction of bending you use most.

– Fixed or variable radius bending in a single cycle: it can mount up to 8 tools at a time, deciding in which position (1, 2, 3, 4 … 8) to put the variable radius.

– It guarantees the maximum repeatability of the part and an unrivalled degree of geometric precisioneven in complex parts.

– It guarantees maximum control of the process: it controls and adjusts to the reactions of the materialand to its elastic return. The ELECT provides several thrust powers (from 2,000 N to 60,000 N), which can be adjusted during the entire bending phase.

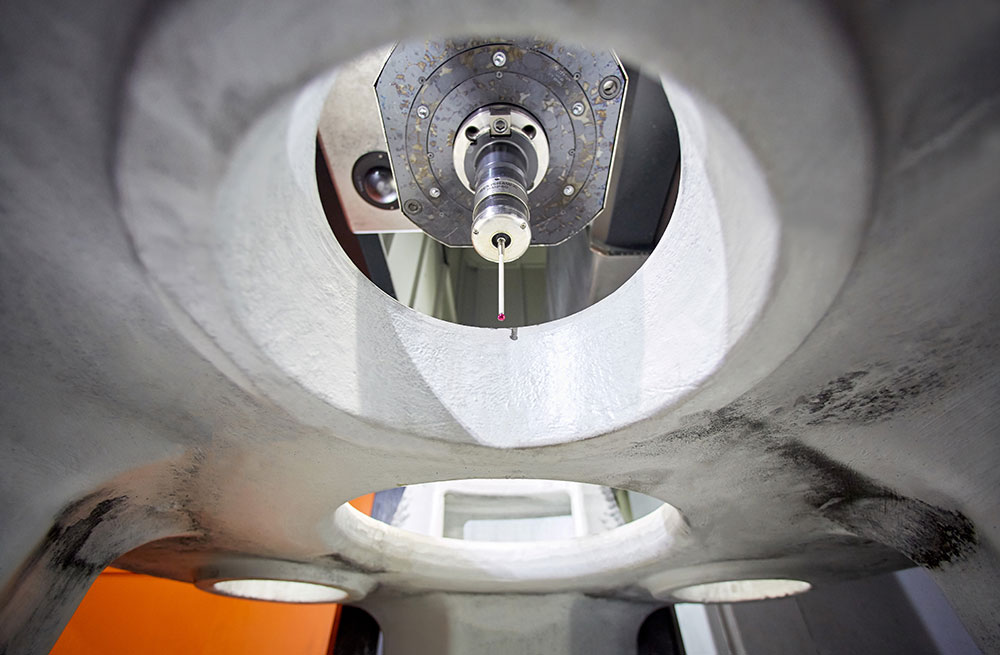

Following the new acquisition and thanks to the investment the company has made, Leku-Ona now has the following bending machines:

- – 1 BLM ELECT (ET 102) Maximum bending capacity from OD: 6mm up to 102mm Fully electric machine with right/left bending and 3D visual graphic programming (VGP3D)

- – 1 BLM E-TURN (ET 52) Maximum bending capacity from OD: 6mm up to 52mm Fully electric machine with right/left bending and 3D visual graphic programming (VGP3D)

- – 2 BLM-SMART Maximum bending capacity OD: 22mm in steel tubes and up to OD: 28 mm in copper, brass or aluminium tubes

- – 1 BLM HYDRAULIC NCS832 Maximum bending capacity up to OD: 30mm

- – 1 AMOB MDH 60 Maximum bending capacity OD: 60mm

- – TUBE END FORMING MACHINES

With these machines the range of solutions offered to our customers continues to increase, in line with the search for excellence that characterises Leku-Ona, at the forefront in the sector.

More info:

LEKU-ONA_Global Solutions

Pol. Industrial Itziar Nave N2B

20829 ITZIAR-DEBA (GIPUZKOA)

T 943 74 34 50

F 943 74 34 62

E leku-ona@leku-ona.com

www.leku-ona.com

Leku-Ona Global Solutions, in its effort to show its processes, services, installations and professionals with total transparency, has launched a Youtube channel, where you can find audiovisual items about the group’s different companies, such as

Leku-Ona Global Solutions, in its effort to show its processes, services, installations and professionals with total transparency, has launched a Youtube channel, where you can find audiovisual items about the group’s different companies, such as

sending...

sending...